NEW

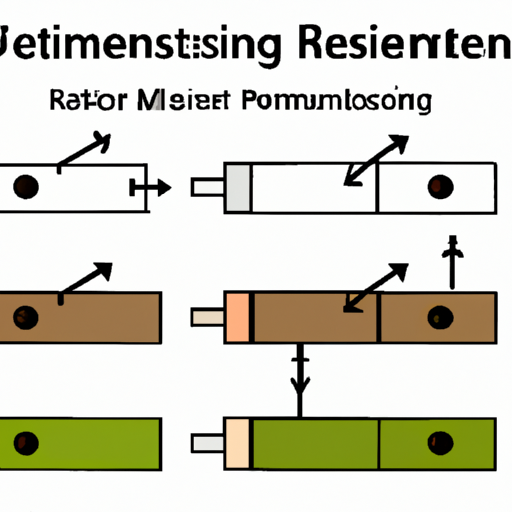

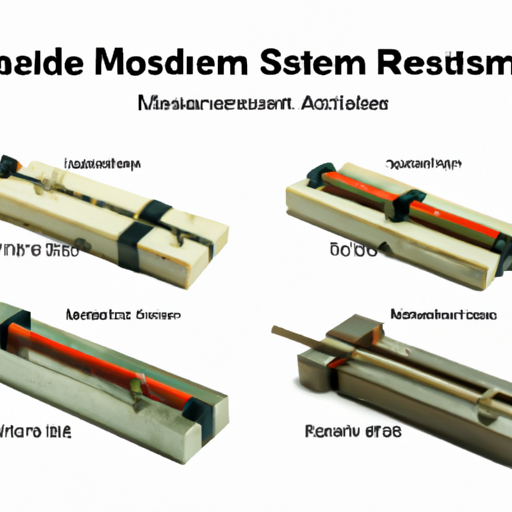

What is the Function of a Resistor? What are the Common Production Processes? I. IntroductionResistors are fundamental components in electrical and electronic circuits, playing a crucial role in controlling the flow of electric current. Defined as passive two-terminal electrical components, resistors limit the amount of current that can pass through a circuit, thereby protecting sensitive components and ensuring proper functionality. Their importance cannot be overstated, as they are integral to a wide range of applications, from consumer electronics to industrial machinery. This blog post will explore the function of resistors, their various types and applications, and the common production processes involved in their manufacturing. II. The Function of a Resistor A. Basic Principles of ResistanceAt the heart of a resistor's function lies the concept of resistance, which is the opposition to the flow of electric current. This relationship is quantitatively described by Ohm’s Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R) of the conductor. Mathematically, this is expressed as:\[ V = I \times R \]The unit of resistance is the ohm (Ω), named after the German physicist Georg Simon Ohm. Understanding this principle is essential for grasping how resistors operate within electrical circuits. B. Role in Electrical CircuitsResistors serve several critical functions in electrical circuits:1. **Current Limiting**: By providing resistance, resistors limit the amount of current that can flow through a circuit. This is particularly important in protecting sensitive components, such as diodes and transistors, from excessive current that could lead to damage.2. **Voltage Division**: Resistors can be used in voltage divider circuits to produce a specific output voltage that is a fraction of the input voltage. This is useful in applications where different components require different voltage levels.3. **Signal Conditioning**: In analog circuits, resistors are often used to shape and condition signals. They can filter out noise, adjust signal levels, and improve the overall performance of the circuit. C. Types of ResistorsResistors come in various types, each designed for specific applications:1. **Fixed Resistors**: These resistors have a constant resistance value and are the most common type used in circuits. They are available in various materials, including carbon, metal film, and wirewound.2. **Variable Resistors (Potentiometers)**: These resistors allow for adjustable resistance values, making them ideal for applications such as volume controls in audio equipment.3. **Specialty Resistors**: This category includes thermistors, which change resistance with temperature, and photoresistors, which change resistance based on light exposure. These resistors are used in temperature sensing and light detection applications. D. Applications of ResistorsResistors are ubiquitous in modern technology, with applications spanning various fields:1. **Consumer Electronics**: Resistors are found in virtually all electronic devices, including smartphones, televisions, and computers, where they help regulate current and voltage.2. **Industrial Equipment**: In industrial settings, resistors are used in control systems, motor drives, and power supplies to ensure safe and efficient operation.3. **Automotive Systems**: Resistors play a vital role in automotive electronics, including engine control units, lighting systems, and infotainment systems, contributing to the overall functionality and safety of vehicles. III. Common Production Processes of ResistorsThe manufacturing of resistors involves several key processes, from material selection to quality control. A. Materials Used in Resistor ManufacturingThe choice of materials is critical in resistor production:1. **Conductive Materials**: Common conductive materials include carbon, metal film, and wirewound elements. Each material offers different characteristics in terms of resistance stability, temperature coefficient, and noise.2. **Insulating Materials**: Insulators are used to encase the resistive element, preventing unwanted current flow and ensuring safety. Common insulating materials include ceramic, epoxy, and plastic. B. Manufacturing TechniquesDifferent types of resistors are produced using specific manufacturing techniques:1. **Carbon Composition Resistors**: - **Mixing and Molding**: Carbon powder is mixed with a binder and molded into the desired shape. - **Cutting and Trimming**: The molded resistors are cut to size and trimmed to achieve the desired resistance value.2. **Metal Film Resistors**: - **Thin Film Deposition**: A thin layer of metal is deposited onto a ceramic substrate using techniques such as sputtering or evaporation. - **Laser Trimming**: A laser is used to precisely trim the metal film, adjusting the resistance value to specifications.3. **Wirewound Resistors**: - **Winding Process**: A resistive wire is wound around a ceramic or plastic core to create the desired resistance. - **Encapsulation**: The wound resistor is then encapsulated in a protective material to enhance durability.4. **Surface Mount Resistors**: - **Screen Printing**: A paste containing conductive material is screen-printed onto a substrate to form the resistor. - **Soldering Techniques**: Surface mount resistors are soldered onto circuit boards using automated processes, allowing for high-density assembly. C. Quality Control MeasuresEnsuring the reliability and performance of resistors is paramount. Common quality control measures include:1. **Testing for Resistance Values**: Each resistor is tested to ensure it meets the specified resistance value, using precision measurement equipment.2. **Environmental Testing**: Resistors undergo environmental testing to assess their performance under various conditions, including temperature and humidity.3. **Reliability Testing**: Long-term reliability tests are conducted to evaluate how resistors perform over time, ensuring they can withstand the rigors of their intended applications. IV. Innovations in Resistor TechnologyAs technology advances, so too does the field of resistor manufacturing. Several key innovations are shaping the future of resistors: A. Advances in Materials ScienceResearch into new materials is leading to the development of resistors with improved performance characteristics, such as higher stability, lower noise, and better thermal management. B. Miniaturization and Surface Mount TechnologyThe trend toward miniaturization in electronics has driven the development of smaller, more efficient surface mount resistors. These components allow for higher circuit density and improved performance in compact devices. C. Smart Resistors and Their ApplicationsEmerging technologies are giving rise to smart resistors that can adapt their resistance based on environmental conditions or circuit requirements. These components have the potential to revolutionize applications in automation, IoT devices, and advanced sensing technologies. V. ConclusionIn summary, resistors are essential components in electrical circuits, serving critical functions such as current limiting, voltage division, and signal conditioning. Their diverse applications span consumer electronics, industrial equipment, and automotive systems. The production processes for resistors involve careful material selection and advanced manufacturing techniques, ensuring high quality and reliability. As technology continues to evolve, innovations in resistor design and manufacturing will pave the way for new applications and improved performance in the ever-changing landscape of electronics. VI. References- Academic Journals- Industry Publications- Online ResourcesThis blog post provides a comprehensive overview of the function and production processes of resistors, highlighting their significance in modern technology and the ongoing innovations that will shape their future.

Application Scenarios for Resistor Supply I. IntroductionIn the world of electronics, resistors play a crucial role in circuit design and functionality. A resistor is a passive electrical component that limits or regulates the flow of electrical current in a circuit. Resistor supply refers to the provision of various types of resistors to meet the diverse needs of electronic applications. Understanding the application scenarios for resistor supply is essential for engineers, designers, and manufacturers, as it helps them select the right components for their projects. This blog post will explore the importance of resistors in electronic circuits and delve into various application scenarios across multiple industries. II. Basic Concepts of Resistors A. What is a Resistor?A resistor is a two-terminal component that resists the flow of electric current, creating a voltage drop across its terminals. The primary function of a resistor is to control the current in a circuit, ensuring that other components operate within their specified limits. B. Types of Resistors1. **Fixed Resistors**: These resistors have a constant resistance value and are widely used in various applications. They come in different resistance values and power ratings, making them suitable for a range of electronic devices.2. **Variable Resistors**: Also known as potentiometers or rheostats, these resistors allow users to adjust the resistance value. They are commonly used in applications where fine-tuning is necessary, such as volume controls in audio equipment.3. **Specialty Resistors**: This category includes resistors designed for specific applications, such as thermistors (temperature-sensitive resistors) and photoresistors (light-sensitive resistors). These components are essential in applications requiring precise control based on environmental conditions. C. Key Specifications1. **Resistance Value**: Measured in ohms (Ω), this value indicates how much the resistor opposes the flow of current.2. **Power Rating**: This specification indicates the maximum power a resistor can dissipate without being damaged, typically measured in watts (W).3. **Tolerance**: This refers to the allowable deviation from the specified resistance value, expressed as a percentage. A lower tolerance indicates a more precise resistor. III. Application Scenarios for Resistor Supply A. Consumer ElectronicsResistors are ubiquitous in consumer electronics, where they are used to ensure proper functionality and performance. 1. **Audio Equipment**: In audio devices, resistors are used in equalizers, amplifiers, and crossovers to manage signal levels and prevent distortion.2. **Home Appliances**: Resistors are found in various home appliances, such as washing machines and microwaves, where they help regulate power and control motor speeds.3. **Mobile Devices**: Smartphones and tablets utilize resistors in their circuits for functions like touch sensitivity, battery management, and signal processing. B. Industrial ApplicationsIn industrial settings, resistors are vital for automation and control systems.1. **Automation Systems**: Resistors are used in sensors and control circuits to ensure accurate readings and reliable operation in automated processes.2. **Robotics**: In robotic systems, resistors help manage power distribution and control signals, ensuring precise movements and actions.3. **Power Management**: Resistors play a critical role in power supply circuits, helping to regulate voltage and current levels in industrial machinery. C. Automotive IndustryThe automotive industry relies heavily on resistors for various electronic systems.1. **Engine Control Units (ECUs)**: Resistors are used in ECUs to manage engine performance, fuel efficiency, and emissions control.2. **Infotainment Systems**: In-car entertainment systems utilize resistors for audio processing, signal conditioning, and user interface controls.3. **Safety Features**: Resistors are integral to safety systems, such as airbags and anti-lock braking systems, where they help ensure reliable operation under various conditions. D. TelecommunicationsIn telecommunications, resistors are essential for signal integrity and processing.1. **Signal Conditioning**: Resistors are used in filters and amplifiers to enhance signal quality and reduce noise in communication systems.2. **Network Equipment**: Routers, switches, and other networking devices rely on resistors for proper signal transmission and power management.3. **RF Applications**: In radio frequency applications, resistors help match impedance and control signal levels, ensuring efficient transmission and reception. E. Medical DevicesThe medical field utilizes resistors in various devices that require precision and reliability.1. **Diagnostic Equipment**: Resistors are used in devices like ECG machines and blood pressure monitors to ensure accurate readings and reliable performance.2. **Monitoring Systems**: In patient monitoring systems, resistors help manage signals from sensors, ensuring that vital signs are accurately displayed.3. **Therapeutic Devices**: Resistors are found in devices like infusion pumps and electrotherapy machines, where they help control current and voltage levels for safe operation. F. Renewable Energy SystemsAs the world shifts towards sustainable energy, resistors play a vital role in renewable energy systems.1. **Solar Inverters**: Resistors are used in solar inverters to manage power conversion and ensure efficient energy transfer from solar panels to the grid.2. **Wind Turbines**: In wind energy systems, resistors help regulate power output and protect sensitive components from voltage spikes.3. **Energy Storage Systems**: Resistors are essential in battery management systems, where they help control charging and discharging processes. G. Research and DevelopmentIn research and development, resistors are crucial for experimentation and prototyping.1. **Prototyping**: Engineers use resistors in prototype circuits to test designs and validate concepts before moving to production.2. **Testing and Measurement**: Resistors are used in testing equipment to calibrate instruments and ensure accurate measurements.3. **Educational Purposes**: In educational settings, resistors are fundamental components in teaching electronics and circuit design principles. IV. Factors Influencing Resistor SelectionWhen selecting resistors for specific applications, several factors must be considered: A. Application RequirementsThe specific needs of the application, such as resistance value, power rating, and tolerance, will dictate the type of resistor required. B. Environmental ConditionsResistors must be chosen based on the environmental conditions they will be exposed to, including temperature, humidity, and potential exposure to chemicals. C. Cost ConsiderationsBudget constraints can influence the choice of resistors, as some specialty resistors may be more expensive than standard options. D. Availability and Supply ChainThe availability of specific resistor types and their supply chain reliability can impact project timelines and costs. V. Future Trends in Resistor SupplyAs technology continues to evolve, several trends are shaping the future of resistor supply: A. Advancements in Material ScienceNew materials are being developed to create resistors with improved performance characteristics, such as higher power ratings and better thermal stability. B. Miniaturization and IntegrationThe trend towards smaller electronic devices is driving the demand for miniaturized resistors that can be integrated into compact circuit designs. C. Smart Resistors and IoT ApplicationsWith the rise of the Internet of Things (IoT), smart resistors that can communicate and adapt to changing conditions are becoming increasingly important. D. Sustainability and Eco-Friendly OptionsAs environmental concerns grow, there is a push for sustainable resistor manufacturing processes and eco-friendly materials. VI. ConclusionResistors are fundamental components in electronic circuits, playing a vital role across various industries. From consumer electronics to renewable energy systems, the application scenarios for resistor supply are diverse and critical for the functionality of modern devices. As technology advances, the importance of resistors will only continue to grow, with new trends shaping their development and application. Understanding these scenarios and trends is essential for anyone involved in electronics, ensuring that the right components are selected for optimal performance and reliability. VII. References1. Academic Journals2. Industry Reports3. Manufacturer Specifications4. Online Resources and TutorialsThis blog post provides a comprehensive overview of the application scenarios for resistor supply, highlighting the importance of resistors in various fields and the factors influencing their selection. As technology continues to evolve, staying informed about these trends will be crucial for engineers and designers alike.

What are the Product Standards for Ceramic Resistors? I. IntroductionCeramic resistors are essential components in the world of electronics, playing a critical role in controlling current flow and ensuring the proper functioning of various devices. These resistors are made from ceramic materials, which provide excellent thermal stability and reliability. As the demand for high-quality electronic components continues to grow, the importance of product standards for ceramic resistors cannot be overstated. This article aims to explore the significance of these standards, the key regulations governing ceramic resistors, and the challenges and future trends in this field. II. Understanding Ceramic Resistors A. Composition and ConstructionCeramic resistors are primarily composed of ceramic materials, which are known for their insulating properties and ability to withstand high temperatures. The most common types of ceramic resistors include thick film and thin film resistors. 1. **Materials Used in Ceramic Resistors**: The core material for ceramic resistors typically includes a mixture of metal oxides, such as tin oxide, which is then processed to create a resistive layer. The choice of materials affects the resistor's performance, including its resistance value, temperature coefficient, and stability.2. **Types of Ceramic Resistors**: - **Thick Film Resistors**: These resistors are made by printing a thick layer of resistive paste onto a ceramic substrate. They are widely used due to their low cost and versatility. - **Thin Film Resistors**: These resistors are created by depositing a thin layer of resistive material onto a substrate. They offer higher precision and stability, making them suitable for applications requiring tight tolerances. B. Applications of Ceramic ResistorsCeramic resistors are utilized in a wide range of electronic devices, from consumer electronics to industrial machinery. Their ability to handle high power and temperature makes them ideal for applications such as:1. **Use in Various Electronic Devices**: Ceramic resistors are commonly found in power supplies, amplifiers, and automotive electronics. They help regulate voltage and current, ensuring the safe operation of these devices.2. **Advantages Over Other Types of Resistors**: Compared to carbon or metal film resistors, ceramic resistors offer superior thermal stability, lower noise, and better performance in high-frequency applications. These advantages make them a preferred choice in many high-performance circuits. III. Importance of Product StandardsProduct standards play a crucial role in the manufacturing and use of ceramic resistors. They ensure that these components meet specific quality and performance criteria, which is vital for the reliability of electronic devices. A. Ensuring Quality and ReliabilityStandards help manufacturers produce consistent and reliable products. By adhering to established guidelines, manufacturers can minimize defects and ensure that their ceramic resistors perform as expected in various applications. B. Facilitating International TradeWith the globalization of the electronics market, product standards facilitate international trade by providing a common framework for quality assurance. This allows manufacturers to sell their products in different countries without facing regulatory hurdles. C. Protecting Consumers and ManufacturersStandards protect consumers by ensuring that the products they purchase are safe and reliable. For manufacturers, compliance with standards can enhance their reputation and reduce liability risks associated with product failures. D. Compliance with Regulatory RequirementsMany industries are subject to strict regulatory requirements. Adhering to product standards helps manufacturers comply with these regulations, ensuring that their products can be legally sold and used in various markets. IV. Key Product Standards for Ceramic ResistorsSeveral key product standards govern the manufacturing and testing of ceramic resistors. These standards can be categorized into international, national, and industry-specific regulations. A. International Standards1. **International Electrotechnical Commission (IEC)**: - **IEC 60115 Series**: This series outlines the general requirements for fixed resistors, including ceramic types. It covers aspects such as resistance values, temperature coefficients, and testing methods. - **IEC 60068 Series**: This series focuses on environmental testing, providing guidelines for assessing the reliability of electronic components under various environmental conditions.2. **International Organization for Standardization (ISO)**: - **ISO 9001 for Quality Management**: This standard sets out the criteria for a quality management system, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements. B. National Standards1. **American National Standards Institute (ANSI)**: ANSI develops standards for various industries, including electronics. Compliance with ANSI standards ensures that ceramic resistors meet specific performance and safety criteria in the U.S. market.2. **European Committee for Standardization (CEN)**: CEN establishes standards for products sold in Europe, ensuring that ceramic resistors meet the necessary quality and safety requirements for European consumers. C. Industry-Specific Standards1. **Automotive Standards (e.g., AEC-Q200)**: The AEC-Q200 standard outlines the qualification requirements for passive components used in automotive applications, ensuring that ceramic resistors can withstand the harsh conditions found in vehicles.2. **Military Standards (e.g., MIL-PRF-55342)**: This standard specifies the performance requirements for resistors used in military applications, ensuring that they can operate reliably in extreme environments. V. Testing and Evaluation MethodsTo ensure compliance with product standards, ceramic resistors undergo rigorous testing and evaluation. These methods assess their electrical, environmental, and reliability performance. A. Electrical Testing1. **Resistance Measurement**: This test measures the resistor's resistance value to ensure it meets specified tolerances. Accurate resistance measurement is crucial for the proper functioning of electronic circuits.2. **Temperature Coefficient of Resistance (TCR)**: TCR testing evaluates how the resistance of a ceramic resistor changes with temperature. A low TCR indicates better stability and performance in varying thermal conditions. B. Environmental Testing1. **Humidity and Temperature Cycling**: This testing simulates real-world conditions by exposing resistors to varying humidity and temperature levels. It helps assess their performance and reliability under extreme environmental conditions.2. **Mechanical Stress Tests**: These tests evaluate the resistor's ability to withstand mechanical stress, such as vibration and shock, which can occur during operation or transportation. C. Reliability Testing1. **Life Testing**: This test assesses the long-term performance of ceramic resistors by subjecting them to continuous operation under specified conditions. It helps predict their lifespan and reliability.2. **Burn-in Testing**: Burn-in testing involves operating the resistors at elevated temperatures and voltages for a specific period. This process helps identify early failures and ensures that only reliable components reach the market. VI. Compliance and Certification A. Role of Certification BodiesCertification bodies play a vital role in ensuring that ceramic resistors meet established product standards. They conduct audits, testing, and evaluations to verify compliance with relevant regulations. B. Process of Obtaining CertificationManufacturers seeking certification must submit their products for testing and evaluation. Once the products meet the required standards, the certification body issues a certificate, allowing the manufacturer to market their products as compliant. C. Importance of Traceability and DocumentationMaintaining traceability and documentation is essential for manufacturers. It ensures that all components can be traced back to their production processes, facilitating quality control and compliance with regulatory requirements. VII. Challenges in Meeting Product StandardsWhile product standards are crucial for ensuring quality and reliability, manufacturers face several challenges in meeting these requirements. A. Variability in Manufacturing ProcessesVariability in manufacturing processes can lead to inconsistencies in product quality. Manufacturers must implement strict quality control measures to minimize this variability and ensure compliance with standards. B. Evolving Technology and StandardsAs technology advances, product standards must also evolve. Manufacturers must stay updated on changes in regulations and adapt their processes accordingly, which can be resource-intensive. C. Cost Implications for ManufacturersMeeting product standards often requires significant investment in testing, quality control, and certification processes. Smaller manufacturers may find it challenging to allocate the necessary resources, potentially impacting their competitiveness. VIII. Future Trends in Ceramic Resistor StandardsThe landscape of ceramic resistor standards is continually evolving, driven by advances in materials and technology. A. Advances in Materials and TechnologyNew materials and manufacturing techniques are being developed to enhance the performance of ceramic resistors. These advancements may lead to the creation of new standards that address the unique properties of these materials. B. Increasing Demand for Miniaturization and EfficiencyAs electronic devices become smaller and more efficient, the demand for miniaturized ceramic resistors is growing. Standards will need to adapt to accommodate these changes while ensuring performance and reliability. C. Potential Changes in Regulatory FrameworksRegulatory frameworks may evolve to address emerging technologies and market demands. Manufacturers must remain vigilant and adaptable to comply with these changes. IX. ConclusionIn conclusion, product standards for ceramic resistors are essential for ensuring quality, reliability, and safety in electronic components. As the electronics industry continues to evolve, manufacturers and consumers must prioritize compliance with these standards to foster innovation and maintain trust in the products they use. By understanding the importance of these standards and the challenges associated with meeting them, stakeholders can work together to ensure the continued success of ceramic resistors in the ever-changing landscape of electronics. X. References1. International Electrotechnical Commission (IEC) Standards2. International Organization for Standardization (ISO) Standards3. American National Standards Institute (ANSI) Guidelines4. European Committee for Standardization (CEN) Publications5. Automotive Electronics Council (AEC-Q200) Standards6. Military Specifications (MIL-PRF-55342)7. Academic Journals on Ceramic Resistors and Standards8. Websites of Certification Bodies and Standard OrganizationsThis comprehensive overview of product standards for ceramic resistors highlights their significance in the electronics industry, providing valuable insights for manufacturers, consumers, and industry stakeholders alike.

What are the Advantages of Resistor Factory Products? I. IntroductionResistors are fundamental components in electronic circuits, serving the critical role of controlling current flow and voltage levels. They are essential for ensuring that electronic devices function correctly and safely. In the fast-paced electronics industry, the demand for high-quality resistors has led to the rise of specialized resistor factories that manufacture these components at scale. This blog post will explore the numerous advantages of using factory-manufactured resistors, highlighting their quality assurance, variety, cost-effectiveness, technical support, innovation, and global reach. II. Quality Assurance A. Consistency in Manufacturing ProcessesOne of the primary advantages of resistor factory products is the consistency achieved through standardized manufacturing processes. Factories employ automated production techniques that minimize human error and ensure uniformity in the resistors produced. This consistency is crucial for electronic applications where precise resistance values are necessary for optimal performance. B. Compliance with Industry StandardsResistor factories often adhere to strict industry standards, which is vital for maintaining quality and safety. Many manufacturers hold ISO certifications, demonstrating their commitment to quality management systems. Additionally, compliance with RoHS (Restriction of Hazardous Substances) regulations ensures that resistors are free from harmful materials, making them safer for both consumers and the environment. C. Reliability and DurabilityFactory-manufactured resistors are designed for long-term performance, which translates to reduced failure rates. The rigorous testing and quality control measures implemented during production ensure that these components can withstand various environmental conditions and electrical stresses. This reliability is essential for applications in critical systems, such as medical devices and aerospace technology. III. Variety and Customization A. Wide Range of Resistor TypesResistor factories offer a diverse array of resistor types to meet the varying needs of the electronics industry. From fixed resistors, which provide a constant resistance value, to variable resistors that allow for adjustable resistance, manufacturers cater to a broad spectrum of applications. Specialty resistors, such as thermistors and photoresistors, are also available, enabling engineers to select the most suitable component for their specific requirements. B. Custom Resistor SolutionsIn addition to standard products, many resistor factories provide custom solutions tailored to unique applications. This capability is particularly beneficial for companies developing specialized electronic devices. Manufacturers can work closely with clients to create resistors that meet specific specifications, whether for prototyping or small-batch production. C. Availability of Different Materials and TechnologiesResistor factories utilize various materials and technologies in their products, including carbon film, metal film, and wire-wound resistors. This variety allows engineers to choose resistors based on their performance needs, such as temperature stability, power rating, and noise characteristics. Furthermore, ongoing innovations in resistor technology continue to enhance performance and efficiency, providing even more options for designers. IV. Cost-Effectiveness A. Economies of Scale in ProductionOne of the most significant advantages of factory-manufactured resistors is the cost-effectiveness achieved through economies of scale. Large-scale production reduces the per-unit cost of resistors, allowing manufacturers to offer competitive pricing. This is particularly advantageous for companies that require large quantities of resistors for their products. B. Reduced Waste and Efficient Resource ManagementResistor factories often implement streamlined manufacturing processes that minimize waste and optimize resource management. By utilizing advanced production techniques and recycling practices, manufacturers can reduce their environmental impact while also lowering costs. This efficiency translates to savings that can be passed on to customers. C. Long-Term Savings Through ReliabilityInvesting in high-quality factory-manufactured resistors can lead to long-term savings for manufacturers. Reliable resistors result in fewer replacements and repairs, reducing maintenance costs over time. Additionally, enhanced performance can lead to lower operational costs, making factory-manufactured resistors a smart investment for businesses. V. Technical Support and Expertise A. Access to Knowledgeable StaffResistor factories often employ knowledgeable staff who can provide valuable technical support to customers. This includes engineering assistance for product selection and guidance on design and integration. Having access to experts can help manufacturers make informed decisions and optimize their designs. B. Comprehensive Documentation and ResourcesFactory-manufactured resistors come with comprehensive documentation, including datasheets and technical specifications. This information is crucial for engineers who need to understand the performance characteristics of the resistors they are using. Additionally, application notes and design guides can provide insights into best practices for integrating resistors into electronic circuits. C. Ongoing Customer SupportMany resistor manufacturers offer ongoing customer support, including warranty and return policies. This commitment to customer satisfaction ensures that clients can rely on their suppliers for assistance with any issues that may arise. Technical assistance and troubleshooting support further enhance the overall customer experience. VI. Innovation and Research & Development A. Investment in R&D by Resistor ManufacturersResistor factories often invest significantly in research and development to stay competitive in the market. This investment leads to the development of new materials and technologies that enhance resistor performance and efficiency. As the electronics industry evolves, manufacturers must adapt to meet the changing needs of their customers. B. Collaboration with Industry PartnersMany resistor manufacturers engage in collaborations with industry partners to drive innovation. Joint ventures and partnerships can lead to the development of cutting-edge products that address emerging challenges in electronics. Additionally, feedback loops from customers help manufacturers refine their products and better meet market demands. C. Staying Ahead of Market TrendsResistor factories that prioritize innovation are better positioned to stay ahead of market trends. By adapting to the evolving needs of the electronics industry and incorporating emerging technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), manufacturers can ensure their products remain relevant and competitive. VII. Global Reach and Distribution A. Availability of Products WorldwideResistor factories often have a global reach, ensuring that their products are available to customers worldwide. This extensive distribution network allows manufacturers to source resistors from reliable suppliers, regardless of their location. Local distributors and representatives further enhance accessibility for customers. B. Fast Delivery and Reduced Lead TimesEfficient inventory management and just-in-time manufacturing practices enable resistor factories to offer fast delivery and reduced lead times. This responsiveness is crucial for manufacturers who need components quickly to meet production schedules. By minimizing delays, resistor factories help their clients maintain a competitive edge. C. Support for International Standards and RegulationsResistor manufacturers that operate on a global scale are well-versed in international standards and regulations. This knowledge facilitates compliance with global requirements, making it easier for customers to navigate the complexities of international trade. By adhering to these standards, manufacturers can ensure their products are accepted in various markets. VIII. ConclusionIn conclusion, the advantages of resistor factory products are numerous and significant. From quality assurance and a wide variety of options to cost-effectiveness and technical support, factory-manufactured resistors play a crucial role in the electronics industry. As technology continues to advance, the importance of high-quality resistors will only grow, making it essential for manufacturers to choose reliable suppliers. The future of resistor manufacturing looks promising, with ongoing innovations and a commitment to meeting the evolving needs of the electronics industry. By leveraging the benefits of factory-manufactured resistors, businesses can enhance their products and drive success in an increasingly competitive market.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change and environmental degradation, the importance of renewable energy has never been more pronounced. Renewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. Transitioning to renewable energy is crucial for reducing greenhouse gas emissions, promoting energy security, and fostering sustainable economic growth. In this article, we will explore the historical context of energy sources, the various types of renewable energy, the role of technology, global trends and policies, economic implications, challenges, and the future of renewable energy. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFossil fuels—coal, oil, and natural gas—have been the backbone of industrial development since the 18th century. Their widespread use has powered economies and transformed societies. However, the environmental consequences of fossil fuel consumption are dire. The burning of fossil fuels releases significant amounts of carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming and climate change. Additionally, fossil fuel extraction and transportation can lead to habitat destruction, oil spills, and air and water pollution. B. The Emergence of Renewable EnergyThe quest for cleaner energy alternatives began in earnest in the late 20th century. Early uses of renewable energy can be traced back to ancient civilizations that harnessed wind for sailing and water for milling grain. However, it wasn't until the 1970s energy crisis that significant investments were made in renewable technologies. Technological advancements, such as the development of photovoltaic cells for solar energy and improved wind turbine designs, have paved the way for modern renewable energy systems. III. Types of Renewable Energy A. Solar EnergySolar energy harnesses sunlight using photovoltaic (PV) panels or solar thermal systems. PV panels convert sunlight directly into electricity, while solar thermal systems use sunlight to heat a fluid that generates steam to drive a turbine. The benefits of solar energy include its abundance, low operating costs, and minimal environmental impact. However, challenges such as high initial costs, land use, and energy storage remain. B. Wind EnergyWind energy is generated by converting the kinetic energy of wind into electricity using wind turbines. These turbines can be installed onshore or offshore, with offshore wind farms often producing more energy due to stronger and more consistent winds. The advantages of wind energy include its low operational costs and minimal emissions. However, challenges such as noise, visual impact, and the need for suitable locations can hinder its expansion. C. HydropowerHydropower generates electricity by harnessing the energy of flowing water, typically through dams. It is one of the oldest and most widely used forms of renewable energy. While hydropower is a reliable and efficient energy source, it can have significant environmental impacts, including habitat disruption and changes to water quality and flow. D. Biomass and BiofuelsBiomass energy is derived from organic materials, such as plant and animal waste. It can be converted into biofuels, such as ethanol and biodiesel, which can replace fossil fuels in transportation. Biomass has the potential to reduce waste and carbon emissions, but its sustainability depends on responsible sourcing and land use practices. E. Geothermal EnergyGeothermal energy taps into the Earth's internal heat to generate electricity or provide direct heating. Geothermal systems can be highly efficient and have a small land footprint. However, their potential is geographically limited to areas with significant geothermal activity, and initial drilling costs can be high. IV. The Role of Technology in Renewable EnergyTechnological innovations are crucial for the growth and efficiency of renewable energy systems. Advances in energy storage, particularly battery technology, have made it possible to store excess energy generated during peak production times for use during periods of low generation. Smart grid technology enhances energy distribution by allowing for real-time monitoring and management of energy flows, improving reliability and efficiency. Additionally, artificial intelligence and data analytics are being employed to optimize energy use, predict demand, and enhance the performance of renewable energy systems. V. Global Trends and Policies in Renewable Energy A. International Agreements and CommitmentsGlobal efforts to combat climate change have led to international agreements, such as the Paris Agreement, which aims to limit global warming to well below 2 degrees Celsius. Countries are increasingly committing to ambitious renewable energy targets, recognizing the need for a transition to sustainable energy systems. B. Government Incentives and SubsidiesMany governments are implementing policies to promote renewable energy adoption, including tax incentives, subsidies, and renewable energy mandates. These measures aim to lower the cost of renewable technologies and encourage investment in clean energy infrastructure. C. Case Studies of Countries Leading in Renewable Energy AdoptionCountries like Germany, Denmark, and China are at the forefront of renewable energy adoption. Germany's Energiewende policy has led to significant investments in solar and wind energy, while Denmark has become a leader in offshore wind energy. China is the largest producer of solar panels and has made substantial investments in renewable energy technologies. VI. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe renewable energy sector is a significant source of job creation. According to the International Renewable Energy Agency (IRENA), the global renewable energy sector employed over 11 million people in 2018, with numbers expected to grow as investments in clean energy continue to rise. B. Cost Comparison: Renewable Energy vs. Fossil FuelsThe cost of renewable energy technologies has decreased dramatically over the past decade, making them increasingly competitive with fossil fuels. In many regions, solar and wind energy are now the cheapest sources of new electricity generation. This trend is expected to continue as technology advances and economies of scale are realized. C. Investment Trends and Future Market PredictionsInvestment in renewable energy is projected to grow significantly in the coming years. According to BloombergNEF, global investment in renewable energy reached $282 billion in 2019, and this figure is expected to rise as countries strive to meet their climate goals and transition to sustainable energy systems. VII. Challenges Facing Renewable Energy Adoption A. Infrastructure LimitationsThe existing energy infrastructure in many regions is primarily designed for fossil fuels, posing challenges for integrating renewable energy sources. Upgrading and expanding the grid to accommodate distributed energy generation is essential for maximizing the potential of renewables. B. Public Perception and MisinformationPublic perception of renewable energy can be influenced by misinformation and misconceptions. Education and outreach efforts are crucial for fostering understanding and acceptance of renewable technologies. C. Policy and Regulatory HurdlesInconsistent policies and regulatory frameworks can hinder the growth of renewable energy. Streamlining permitting processes and creating stable policy environments are essential for encouraging investment and innovation in the sector. VIII. The Future of Renewable Energy A. Emerging Technologies and Their Potential ImpactEmerging technologies, such as floating solar panels, advanced energy storage solutions, and hydrogen fuel cells, hold great promise for the future of renewable energy. These innovations could enhance energy generation, storage, and distribution, further accelerating the transition to a sustainable energy future. B. The Role of Individuals and Communities in Promoting Renewable EnergyIndividuals and communities play a vital role in promoting renewable energy adoption. Grassroots movements, local initiatives, and community solar projects can drive demand for clean energy and influence policy decisions at the local and national levels. C. Vision for a Sustainable Energy FutureA sustainable energy future is one where renewable energy sources dominate the energy landscape, reducing reliance on fossil fuels and minimizing environmental impacts. Achieving this vision requires collaboration among governments, businesses, and individuals to create a resilient and equitable energy system. IX. ConclusionThe transition to renewable energy is not just a necessity; it is an opportunity to create a sustainable future for generations to come. By embracing renewable technologies, we can combat climate change, promote economic growth, and enhance energy security. It is imperative that individuals, businesses, and governments take action to support the growth of renewable energy. Together, we can pave the way for a cleaner, greener, and more sustainable world. X. References1. International Renewable Energy Agency (IRENA). (2019). Renewable Energy and Jobs – Annual Review 2019.2. BloombergNEF. (2020). New Energy Outlook 2020.3. United Nations Framework Convention on Climate Change (UNFCCC). (2015). Paris Agreement.4. U.S. Department of Energy. (2020). 2020 Wind Technologies Market Report.5. International Energy Agency (IEA). (2020). World Energy Outlook 2020.This blog post provides a comprehensive overview of the evolution of renewable energy, highlighting its importance, types, technological advancements, global trends, economic implications, challenges, and future prospects. By understanding the significance of renewable energy, we can collectively work towards a sustainable future.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change and environmental degradation, the shift towards renewable energy has never been more critical. Renewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. The importance of renewable energy lies not only in its potential to reduce greenhouse gas emissions but also in its ability to provide sustainable energy solutions for future generations. This article will explore the historical context of energy sources, the various types of renewable energy, the role of technology, global trends and policies, economic implications, challenges, and the future of renewable energy. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFor centuries, fossil fuels—coal, oil, and natural gas—have been the backbone of global energy production. The Industrial Revolution marked a significant turning point, as the demand for energy surged, leading to an increased reliance on these finite resources. However, the environmental consequences of fossil fuel consumption have become increasingly apparent, including air and water pollution, habitat destruction, and climate change. B. The Emergence of Renewable EnergyIn response to the environmental crisis, the late 20th century saw a renewed interest in renewable energy sources. Early uses of windmills for grinding grain and solar energy for heating water laid the groundwork for modern renewable technologies. Technological advancements, such as the development of photovoltaic cells and more efficient wind turbines, have propelled renewable energy into the mainstream, making it a viable alternative to fossil fuels. III. Types of Renewable Energy A. Solar EnergySolar energy harnesses the power of the sun through photovoltaic panels that convert sunlight into electricity. The benefits of solar energy include its abundance and the fact that it produces no emissions during operation. However, challenges such as high initial costs, land use, and energy storage remain. B. Wind EnergyWind energy is generated by converting the kinetic energy of wind into electricity using wind turbines. This form of energy is clean and renewable, with the potential to power millions of homes. However, wind energy faces limitations, including variability in wind patterns and concerns about noise and wildlife impact. C. HydropowerHydropower generates electricity by using the flow of water to turn turbines. It is one of the oldest and most established forms of renewable energy. While hydropower is efficient and reliable, it can have significant environmental impacts, such as habitat disruption and changes in water quality. D. Biomass and BiofuelsBiomass refers to organic materials, such as plant and animal waste, that can be converted into energy. Biofuels, derived from biomass, are used as alternatives to gasoline and diesel. While biomass can help reduce waste and provide energy, concerns about land use and food production must be addressed. E. Geothermal EnergyGeothermal energy harnesses heat from the Earth’s core to generate electricity or provide direct heating. This renewable source is reliable and has a small land footprint. However, its potential is limited to regions with suitable geological conditions, and the initial costs can be high. IV. The Role of Technology in Renewable EnergyTechnological innovations are crucial for the advancement of renewable energy. Energy storage solutions, such as advanced batteries, are essential for managing the intermittent nature of solar and wind energy. Smart grid technology enhances energy distribution efficiency, allowing for better integration of renewable sources into existing infrastructure. Additionally, artificial intelligence and data analytics play a significant role in optimizing energy use, predicting demand, and improving system reliability. V. Global Trends and Policies in Renewable Energy A. International Agreements and CommitmentsGlobal efforts to combat climate change have led to international agreements, such as the Paris Agreement, which aims to limit global warming to well below 2 degrees Celsius. These commitments have spurred countries to invest in renewable energy and reduce their reliance on fossil fuels. B. Government Incentives and SubsidiesMany governments offer incentives and subsidies to promote renewable energy adoption. These can include tax credits, grants, and feed-in tariffs, which encourage individuals and businesses to invest in renewable technologies. C. Case Studies of Countries Leading in Renewable Energy AdoptionCountries like Germany, Denmark, and China have emerged as leaders in renewable energy adoption. Germany’s Energiewende policy aims to transition to a sustainable energy system, while Denmark has become a pioneer in wind energy. China, the world’s largest producer of solar panels, is investing heavily in renewable energy to meet its growing energy demands. VI. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe transition to renewable energy has significant economic implications, particularly in job creation. The renewable energy sector has proven to be a major source of employment, with jobs in manufacturing, installation, and maintenance of renewable technologies. B. Cost Comparison Between Renewable and Non-Renewable Energy SourcesThe cost of renewable energy has decreased dramatically in recent years, making it competitive with traditional fossil fuels. According to the International Renewable Energy Agency (IRENA), the cost of solar photovoltaic electricity has fallen by over 80% since 2010, making it one of the cheapest sources of new electricity generation. C. Investment Trends and Future Outlook for Renewable Energy MarketsInvestment in renewable energy is on the rise, with billions of dollars flowing into the sector annually. As technology continues to improve and costs decrease, the future outlook for renewable energy markets appears promising, with projections indicating continued growth in capacity and investment. VII. Challenges Facing Renewable Energy Adoption A. Infrastructure Limitations and Grid IntegrationOne of the primary challenges facing renewable energy adoption is the existing infrastructure. Many power grids are not equipped to handle the variability of renewable energy sources, necessitating significant upgrades and investments in grid integration. B. Public Perception and MisinformationPublic perception of renewable energy can be influenced by misinformation and lack of understanding. Education and outreach efforts are essential to dispel myths and promote the benefits of renewable energy. C. Policy and Regulatory HurdlesPolicy and regulatory frameworks can either facilitate or hinder the growth of renewable energy. Inconsistent policies, lack of long-term planning, and regulatory barriers can create uncertainty for investors and developers. VIII. The Future of Renewable Energy A. Predictions for Renewable Energy GrowthExperts predict that renewable energy will continue to grow rapidly in the coming decades. The International Energy Agency (IEA) forecasts that renewables will account for nearly 80% of global electricity generation by 2050. B. The Role of Innovation and Research in Shaping the FutureOngoing research and innovation are critical for overcoming the challenges facing renewable energy. Breakthroughs in energy storage, grid technology, and efficiency improvements will play a vital role in shaping the future energy landscape. C. The Importance of Public Engagement and EducationPublic engagement and education are essential for fostering support for renewable energy initiatives. By raising awareness of the benefits and addressing concerns, communities can work together to create a sustainable energy future. IX. ConclusionThe evolution of renewable energy represents a crucial step towards a sustainable future. As we face the challenges of climate change and environmental degradation, the transition to renewable energy sources is not just an option; it is a necessity. Individuals, businesses, and governments must work together to embrace renewable energy, invest in innovative technologies, and advocate for supportive policies. By doing so, we can pave the way for a cleaner, more sustainable energy future for generations to come. X. References1. International Renewable Energy Agency (IRENA). (2021). Renewable Power Generation Costs in 2020.2. International Energy Agency (IEA). (2021). World Energy Outlook 2021.3. United Nations Framework Convention on Climate Change (UNFCCC). (2015). The Paris Agreement.4. U.S. Department of Energy. (2020). Renewable Energy: A Key to a Sustainable Future.5. European Commission. (2020). The European Green Deal. This blog post provides a comprehensive overview of the evolution of renewable energy, highlighting its significance, challenges, and future prospects. By understanding the importance of renewable energy, we can collectively work towards a sustainable future.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionAs the world grapples with the pressing challenges of climate change and environmental degradation, the importance of renewable energy has never been more pronounced. Renewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. The transition to renewable energy is crucial in combating climate change, reducing greenhouse gas emissions, and fostering a sustainable future. This article will explore the historical context of energy sources, the various types of renewable energy, the role of technology, economic implications, global perspectives, future trends, and the overarching importance of this transition. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFor centuries, fossil fuels—coal, oil, and natural gas—have been the backbone of global energy consumption. The Industrial Revolution marked a significant increase in fossil fuel usage, leading to unprecedented economic growth. However, this reliance on fossil fuels has come at a steep environmental cost. The burning of fossil fuels releases significant amounts of carbon dioxide (CO2) and other greenhouse gases into the atmosphere, contributing to global warming and climate change. Additionally, fossil fuel extraction and consumption have led to air and water pollution, habitat destruction, and health issues for communities worldwide. B. The Emergence of Renewable EnergyIn response to the environmental consequences of fossil fuel dependency, renewable energy began to gain traction in the late 20th century. Early uses of renewable energy can be traced back to ancient civilizations that harnessed wind and water for power. However, it was not until the 1970s energy crisis that significant investments were made in renewable technologies. Technological advancements, such as improved solar panel efficiency and wind turbine design, have paved the way for modern renewable energy systems, making them more viable and cost-effective. III. Types of Renewable Energy A. Solar EnergySolar energy harnesses the power of the sun through photovoltaic (PV) cells that convert sunlight into electricity. Solar panels can be installed on rooftops or in large solar farms, providing a clean and abundant energy source. The benefits of solar energy include its low operating costs and minimal environmental impact. However, challenges such as high initial installation costs and energy storage limitations during non-sunny periods remain. B. Wind EnergyWind energy is generated by converting the kinetic energy of wind into electricity using wind turbines. These turbines can be installed onshore or offshore, with offshore wind farms often producing more energy due to stronger and more consistent winds. The advantages of wind energy include its low emissions and the ability to generate electricity at a competitive cost. However, challenges such as noise, visual impact, and the need for suitable locations can limit its deployment. C. HydropowerHydropower is one of the oldest and most widely used forms of renewable energy, generated by harnessing the energy of flowing water, typically through dams. Hydroelectric power plants can provide a stable and reliable energy source, often capable of generating electricity on demand. However, environmental considerations, such as the impact on aquatic ecosystems and displacement of communities, must be carefully managed. D. Biomass and BiofuelsBiomass refers to organic materials, such as plant and animal waste, that can be converted into energy. Biofuels, derived from biomass, can be used as alternatives to gasoline and diesel. While biomass can help reduce waste and provide a renewable energy source, concerns about land use, food production, and emissions from biofuel combustion must be addressed. E. Geothermal EnergyGeothermal energy harnesses heat from the Earth’s interior to generate electricity or provide direct heating. Geothermal systems can be highly efficient and have a small land footprint. However, the potential for geothermal energy is geographically limited, and the initial costs for drilling and infrastructure can be high. IV. The Role of Technology in Renewable EnergyTechnological advancements play a crucial role in the growth and efficiency of renewable energy systems. Innovations in energy storage, such as lithium-ion batteries, have made it possible to store excess energy generated during peak production times for use during periods of low generation. Smart grid technology enhances energy distribution, allowing for better integration of renewable sources into the existing energy infrastructure. Additionally, artificial intelligence and data analytics are being utilized to optimize energy use, predict demand, and improve the efficiency of renewable energy systems. V. Economic Implications of Renewable EnergyThe transition to renewable energy has significant economic implications. The renewable energy sector has become a major source of job creation, with millions of jobs in solar, wind, and other renewable industries. As technology advances and production scales up, the cost of renewable energy continues to decline, making it increasingly competitive with fossil fuels. Government policies and incentives, such as tax credits and subsidies, are also crucial in promoting renewable energy adoption and driving investment in clean technologies. VI. Global Perspectives on Renewable Energy A. Case Studies of Countries Leading in Renewable Energy AdoptionSeveral countries have emerged as leaders in renewable energy adoption. Germany’s Energiewende (energy transition) policy aims to shift the country towards a sustainable energy system, significantly increasing the share of renewables in its energy mix. China has made substantial investments in solar and wind energy, becoming the world’s largest producer of solar panels and wind turbines. The United States has also made strides in renewable energy initiatives, with states like California leading the way in solar energy production. B. Challenges Faced by Developing Countries in Adopting Renewable EnergyWhile many developed countries are making progress in renewable energy adoption, developing countries face unique challenges. Limited access to financing, inadequate infrastructure, and political instability can hinder the deployment of renewable technologies. However, international cooperation and investment can help overcome these barriers, enabling developing nations to harness their renewable energy potential. VII. Future Trends in Renewable EnergyThe future of renewable energy looks promising, with predictions indicating continued growth in the sector. International agreements, such as the Paris Agreement, emphasize the need for countries to reduce greenhouse gas emissions and transition to cleaner energy sources. Innovations on the horizon, such as floating solar farms and advanced nuclear technologies, hold the potential to further diversify and enhance the renewable energy landscape. VIII. ConclusionThe transition to renewable energy is not just an environmental imperative; it is a pathway towards a sustainable future. As we face the challenges of climate change, energy security, and economic inequality, embracing renewable energy sources offers a viable solution. Individuals, businesses, and governments must work together to promote renewable energy adoption, invest in innovative technologies, and create policies that support a sustainable energy future. By doing so, we can envision a world powered by clean, renewable energy, ensuring a healthier planet for generations to come. IX. References1. International Energy Agency (IEA). (2021). World Energy Outlook 2021.2. U.S. Department of Energy. (2020). Renewable Energy: A Key to a Sustainable Future.3. REN21. (2021). Renewables 2021 Global Status Report.4. World Bank. (2020). The World Bank and Renewable Energy.5. United Nations. (2015). Paris Agreement. This blog post provides a comprehensive overview of the evolution of renewable energy, highlighting its importance, types, technological advancements, economic implications, global perspectives, and future trends. The transition to renewable energy is essential for a sustainable future, and collective action is needed to realize this vision.

The Evolution of Renewable Energy: A Path Towards a Sustainable Future I. IntroductionRenewable energy refers to energy derived from natural sources that are replenished at a faster rate than they are consumed. This includes solar, wind, hydro, biomass, and geothermal energy. As the world grapples with the pressing challenges of climate change, the importance of renewable energy has never been more pronounced. Transitioning to renewable energy sources is crucial for reducing greenhouse gas emissions, enhancing energy security, and fostering sustainable economic growth. This article will explore the historical context of energy sources, the various types of renewable energy, the role of technology, global trends and policies, economic implications, challenges, and the future of renewable energy. II. Historical Context of Energy Sources A. Traditional Energy Sources: Fossil Fuels and Their ImpactFossil fuels—coal, oil, and natural gas—have been the backbone of industrial development since the 18th century. The Industrial Revolution marked a significant increase in fossil fuel consumption, leading to unprecedented economic growth. However, this reliance on fossil fuels has come at a steep environmental cost. The burning of fossil fuels releases carbon dioxide and other greenhouse gases, contributing to global warming and air pollution. The consequences of this energy model are evident in rising global temperatures, extreme weather events, and deteriorating public health. B. The Emergence of Renewable EnergyThe quest for alternative energy sources began in earnest in the late 20th century as awareness of environmental issues grew. Early uses of renewable energy can be traced back to ancient civilizations that harnessed wind and water for power. However, it was not until the 1970s energy crisis that significant investments were made in renewable technologies. Technological advancements, such as improved solar panel efficiency and wind turbine design, have paved the way for modern renewable energy systems. III. Types of Renewable Energy A. Solar EnergySolar energy harnesses sunlight through photovoltaic cells or solar thermal systems. Photovoltaic panels convert sunlight directly into electricity, while solar thermal systems use sunlight to heat water or air for residential and commercial use. The benefits of solar energy include its abundance and decreasing costs, making it increasingly accessible. However, challenges such as energy storage and intermittent supply remain. B. Wind EnergyWind energy is generated by converting the kinetic energy of wind into electricity using wind turbines. Wind farms can be located onshore or offshore, with offshore wind farms often producing more energy due to stronger and more consistent winds. The advantages of wind energy include its low operational costs and minimal environmental impact. However, challenges such as noise, visual impact, and the need for suitable locations can hinder development. C. HydropowerHydropower generates electricity by harnessing the energy of flowing water, typically through dams. It is one of the oldest and most widely used forms of renewable energy. While hydropower is a reliable and efficient energy source, it can have significant environmental impacts, including habitat disruption and changes to water quality and flow. D. Biomass and BiofuelsBiomass refers to organic materials, such as plant and animal waste, that can be converted into energy. Biofuels, derived from biomass, can be used as alternatives to gasoline and diesel. While biomass can help reduce waste and provide energy, concerns about land use, food production, and emissions from biofuel combustion must be addressed. E. Geothermal EnergyGeothermal energy harnesses heat from the Earth’s interior to generate electricity or provide direct heating. It is a reliable and consistent energy source, with a small land footprint. However, geothermal energy is location-dependent, and the initial costs of drilling and infrastructure can be high. IV. The Role of Technology in Renewable EnergyTechnological innovations play a crucial role in the advancement of renewable energy. Energy storage technologies, such as lithium-ion batteries, are essential for managing the intermittent nature of solar and wind energy. Smart grid technology enhances energy distribution and efficiency, allowing for better integration of renewable sources into existing power grids. Additionally, artificial intelligence and data analytics are increasingly being used to optimize energy use, predict demand, and improve system reliability. V. Global Trends and Policies in Renewable Energy A. International Agreements and CommitmentsGlobal efforts to combat climate change have led to international agreements, such as the Paris Agreement, which aims to limit global warming to well below 2 degrees Celsius. Countries are committing to reducing greenhouse gas emissions and increasing the share of renewable energy in their energy mix. B. Government Incentives and SubsidiesMany governments offer incentives and subsidies to promote renewable energy adoption. These can include tax credits, grants, and feed-in tariffs that guarantee a fixed price for renewable energy producers. Such policies have been instrumental in driving down costs and increasing the deployment of renewable technologies. C. Case Studies of Countries Leading in Renewable Energy AdoptionCountries like Germany, Denmark, and China are at the forefront of renewable energy adoption. Germany’s Energiewende (energy transition) policy has led to significant investments in solar and wind energy. Denmark generates a substantial portion of its electricity from wind, while China is the world’s largest producer of solar panels and wind turbines. VI. Economic Implications of Renewable Energy A. Job Creation in the Renewable Energy SectorThe transition to renewable energy is creating millions of jobs worldwide. From manufacturing and installation to maintenance and research, the renewable energy sector offers diverse employment opportunities. According to the International Renewable Energy Agency (IRENA), the sector employed over 11 million people globally in 2018, with numbers expected to grow. B. Cost Comparison Between Renewable and Non-Renewable Energy SourcesThe cost of renewable energy has plummeted in recent years, making it competitive with, and often cheaper than, fossil fuels. The levelized cost of electricity (LCOE) for solar and wind has decreased significantly, leading to increased investment and deployment. C. Investment Trends and Future Outlook for Renewable Energy MarketsInvestment in renewable energy continues to rise, driven by technological advancements, policy support, and growing public awareness of climate change. The global renewable energy market is expected to grow substantially in the coming years, with projections indicating that renewables could account for a significant share of global energy consumption by 2050. VII. Challenges Facing Renewable Energy Adoption A. Infrastructure Limitations and Grid IntegrationOne of the primary challenges facing renewable energy adoption is the need for updated infrastructure. Many existing power grids are not equipped to handle the variability of renewable energy sources. Upgrading grid infrastructure and developing energy storage solutions are essential for facilitating the transition. B. Public Perception and MisinformationPublic perception of renewable energy can be influenced by misinformation and lack of understanding. Education and outreach efforts are crucial for dispelling myths and promoting the benefits of renewable energy. C. Policy and Regulatory HurdlesInconsistent policies and regulatory frameworks can hinder renewable energy development. Streamlining permitting processes and creating stable policy environments are essential for encouraging investment and innovation. VIII. The Future of Renewable Energy A. Predictions for Renewable Energy GrowthThe future of renewable energy looks promising, with continued growth expected across all sectors. As technology advances and costs decrease, renewable energy is likely to become the dominant source of energy globally. B. The Role of Innovation and Research in Shaping the FutureOngoing research and innovation will be critical in addressing the challenges facing renewable energy. Breakthroughs in energy storage, grid management, and efficiency will play a vital role in shaping a sustainable energy future. C. The Importance of Public Engagement and EducationPublic engagement and education are essential for fostering support for renewable energy initiatives. By raising awareness of the benefits and opportunities associated with renewable energy, individuals and communities can play an active role in the transition to a sustainable future. IX. ConclusionThe significance of renewable energy in combating climate change and promoting sustainable development cannot be overstated. As we move towards a future powered by renewable energy, it is essential for individuals, businesses, and governments to take action. By investing in renewable technologies, supporting policies that promote sustainability, and engaging in public discourse, we can collectively work towards a sustainable future powered by clean, renewable energy. X. References1. International Renewable Energy Agency (IRENA). (2019). Renewable Energy and Jobs – Annual Review 2019.2. United Nations Framework Convention on Climate Change (UNFCCC). (2015). Paris Agreement.3. U.S. Department of Energy. (2020). 2020 Wind Technologies Market Report.4. International Energy Agency (IEA). (2021). World Energy Outlook 2021.5. Global Wind Energy Council (GWEC). (2021). Global Wind Report 2021.This blog post provides a comprehensive overview of the evolution of renewable energy, highlighting its importance, challenges, and future prospects. By understanding the historical context and current trends, we can better appreciate the role of renewable energy in creating a sustainable future.